Penergetic @2019 | website by: Whistler Web & Print

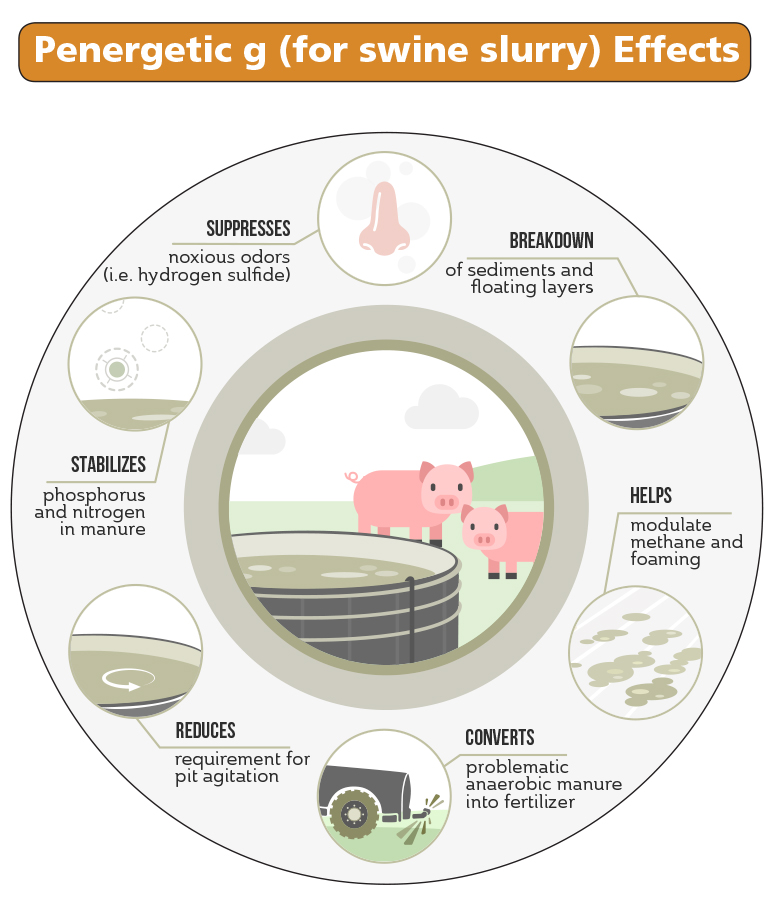

Optimal Liquid Manure Treatment

- Eliminates unpleasant ammonia and sulphur odors

- Controls crust and/or sediment layer formation

- Causes slurry to become homogenous

- Addresses insects and manure-borne pathogens

- Better for soil and crops while protecting groundwater

Slurry Activator

“Converting a problematic waste product into a valuable organic fertilizer.”

Suitable for dairy, hog, other livestock liquid manure, penergetic g acts as a catalyst to naturally create an aerobic condition in the slurry, activating beneficial microbes which transform the slurry into a nutrient rich organic fertilizer – which is far more beneficial than the more commonly occurring and problematic untreated (anaerobic) manure or slurry.

Penergetic g is an economical, easy to apply manure treatment method (requiring no capital equipment) used by thousands of dairy farms in Europe, globally (and now popular in North America).

BENEFITS

- Optimizes slurry and liquid manure

- Stimulates the more complete breakdown of slurry by decomposition/rotting (aerobic process), instead of the more common and less desirable putrefaction & decay (anaerobic process)

- Overcomes the emission of malodorous gases, including hydrogen sulphide, ammonia & (odourless) methane gas

- Activates the conversion of ammonia to ammonium (a valuable plant nutrient) resulting in less loss of nitrogen through volatilization (gassing off)

- Mitigates blocked effluent channels and pits and stops crust formation and bottom sedimentation layers

- Produces a homogeneous and free flowing slurry

- Lessens or eliminates the need for agitation of stored slurry

- For barns with sand bedding, prevents manure solids from sticking to sand so lagoon retains more storage capacity and more nutrients available for field application

- Overcomes problem of foaming, including when pumping out

- Higher available nutrient value permits requirements for synthetic fertilizer and farm chemicals to be reduced

- Reduces causticity for better compatibility with plants and soil microbes

- Reduces the occurrence of harmful insect and insect larvae

- Limits probability of pathogenic organisms in slurry

- Stabilizes manure nutrients resulting in a reduced risk of nutrients leaching into water resources

- Optimizes manuring effect which activates the soil and contributes to plant nourishment

- Creates a valuable organic fertilizer that delivers more balanced nutrients to plants and soil

- No chemical ingredients, no capital investment and energy consumption reduced

- Environmentally friendly and ecologically balanced (OMRI listed)

APPLICATIONS

Penergetic g is easy to apply:

- in the barn effluent channels / scraper alleys

- into underground pits, including through slatted flooring

- directly into a storage tank or lagoon

* Also works well with flush barn set-up or when sand bedding is used.

APPLICATION GUIDELINES

Shock Treatment of Manure Pits and Lagoons

When first starting on the Penergetic products it is important to apply an initial one-time shock to the existing manure/sludge/slurry that is currently in the pit or lagoon. The suggestion is to use 1.5 to 2 kg per 100 m3 (25,000 gallons) of volume present depending on severity or thickness of sludge. Preferred method is to mix powder in water and apply directly into the liquid portion of the manure.

*Product will not work if poured on top of a crust.

Example: Example: 800 m3 (200,000 gallons) of existing volume to treat: 200,000 / 25,000 = 8 x (1.5 to 2.0 kg) or 12 to 16 kg. for initial shock treatment.

Weekly or Bi-Weekly application rates (based on animal numbers or volume)

Dairy: Suggested application rate is to apply 5 grams of product per week for full size dairy cows.

Example: 200 cows = 5 X 200 = 1.0 kg per week. If producer prefers to apply every 2 weeks then apply 2 kg every 2 weeks for 200 cows.

Swine: Depending on operation set-up, add penergetic g to underground pit based on LSUs or volume of manure generated. In cases where in-barn pits emptied at regular intervals – say, monthly, half yearly or annually, can match application rate and intervals accordingly

Example: Suggested application rate is to apply 200 grams of product for every 100 sows per week, or 8 kg of product per 400 m3 (100,000 gallons) of manure produced. Alternatively, see (Sample) Swine Manure Treatment Protocol PDF which follows in Information Download section.

** Contact distributor for details on LSU equivalents

e.g.: a cow = 1 LSU; heifer = 0.7 LSU; sow = 0.4 LSU; wieners up to 50 lbs. = 0.06 LSU, feeders: 7 = 1 LSU, etc.

**Accelerated Rate is suggested for severe situations: e.g. 2x rate for the first 12 to 15 weeks of use.

RECOMMENDED METHOD OF APPLICATION

RECOMMENDED METHOD OF APPLICATION

a. In barn alleys or effluent channels without a floating layer

Mix penergetic g with plenty of water in a watering can and pour evenly over the channel or through slatted flooring. Best results may be achieved by pouring 2/3rds of the recommended dosage at the head of the channel. In barns with automatic alley scrappers, the scrappers will carry the penergetic g/water mix out with the slurry to the pit or tank.

b. In pits or effluent channels with a crust layer

Poke some holes through the crust layer (or move the crust layer aside) and pour the mixture of penergetic g and water through these holes into the liquid layer of the slurry under the crust.

c. In a slurry tank or lagoon

For best results at the outset, pour the penergetic g/water mixture over the agitator while operational. If no agitator is available, puncture any crust layer present with a suction hose and introduce the penergetic g/water mixture through the hose. Pump sufficient slurry out of the tank or lagoon to fill the suction tank then pump it back into the slurry tank/lagoon. The idea is the get the penergetic g / water mixture integrated into the slurry as much as possible at the outset so as to ensure good results more quickly. In the case of large slurry tanks or lagoons, especially if a thick crust is present at the outset (dairy) or heavy sediment layer (hog), this procedure should be repeated at several locations around the structure.

d. In underground pits and stall cleanout channels

Mix penergetic g with plenty of water in a watering can and pour it evenly over the empty pit or channel. Repeat this procedure each time the channel or pit is drained.

e. Maintenance application

On an on-going basis, to treat manure that continues to be generated, penergetic g mixed with plenty of water is applied through the slatted flooring or into the manure alleys in the barn. This maintenance application should be carried out regularly, usually weekly, but at least every 14 days.

PRODUCT FORMS

| Product Descriptor | Purpose |

|---|---|

| Penergetic g for slurry activator | for regular liquid dairy manure/slurry |

| Penergetic g/k for slurry with fiber | for liquid dairy manure with extra bedding (fiber) in mixture |

| (New) Penergetic g/k molasses | for liquid dairy manure with extra fiber |

| Penergetic g for pig slurry | for regular liquid swine manure/slurry |

| Penergetic g/k for pig slurry | for liquid swine manure/slurry with extra fiber or carpeting/crusting |

| Penergetic g/k/f for pig slurry | for liquid swine manure/slurry with foaming |

PRODUCT SIZE

| Powder format (calcium carbonate) | 10 kg |

| 10 litres |

Cost Savings

- no capital equipment (or capital expenditures) required

- no aeration equipment

- minimal agitation required (sometimes none)

- lower energy costs

- reduced need for barn ventilation equipment & cost

- no need for lagoon cover (for odour containment)

- reduced need for soil incorporation/injection

BEST OF ALL!

By recirculating treated manure – a higher value, nutrient-rich organic fertilizer (superior to untreated manure) – back to the land:

- The need for (and cost of) other forms of nutrients (synthetic fertilizer) is reduced

- transportation and manure spreading expense reduced versus using less fertile untreated manure

- disease and insect suppression expenses also reduced

≈ Using penergetic g permits manure management to be turned from a cost center into a “profitable”

value-added proposition. ≈

MODE OF ACTION

Penergetic g uses a proprietary process which activates the aerobic microorganisms, stops the putrefaction process and stimulates the beneficial decomposition/rotting process.

HOW PENERGETIC G WORKS

Penergetic g works so effectively because it activates an aerobic process in the slurry. How is this achieved and why it is advantageous are described below:

TRANSFORMING A PROBLEMATIC WASTE INTO A VALUABLE ORGANIC FERTILIZER

Slurry as a “problem situation” requiring resolution

The daily problems involving slurry are familiar to any dairy or pig farmer: blocked effluent channels, floating layers and solidified sedimentation layers in the slurry tanks, the need for extensive lagoon agitation before applying the slurry, an acrid, pungent smell in the area of barns and pits, gas emissions during agitation and application of the slurry, burning and scorching of the crops after application and many other problems. Often despite the farmer’s best efforts, the slurry fails to produce the desired fertilizing effect. This leads to the application of additional fertilizers and other crop protection measures.

The underlying problem – putrefaction

Typically, slurry will become a problematic waste product when conversion takes place by means of putrefaction processes. This involves decay under anaerobic conditions, i.e. in the absence of oxygen. Anaerobic conversion of slurry leads to the development of malodorous gases, including hydrogen sulphide and ammonia, and (odourless) methane gas. Also problematic, the odour carriers in manure – indole and skatole (3-methylindole) – attract harmful insects. These insects lay their eggs in the slurry, and the subsequent larvae often remain in the slurry when it is applied on the fields, leading to crop damage and the need to apply pesticides. Furthermore, the valuable substance ammonium nitrogen is lost in the anaerobic slurry, because ammonium is converted into ammonia, through volatilization, and consequently is no longer available as a nutrient for plants.

Oxygen through aeration?

The conventional method of introducing oxygen into the slurry involves mechanical aeration by means of stirrers or compressors. However, this technical method becomes problematic when dealing with large quantities of slurry which cannot be stirred effectively every day. Floating layers then quickly form, further sealing off the slurry from the oxygen supply and thus strengthening the anaerobic environment. Also, the annual energy costs for stirring/agitation operations can be considerable.

The natural solution – decomposition

But there is another way! The simple and natural solution to turn slurry into a valuable organic fertilizer involves activating decomposition processes in the slurry which only take place with oxygen. The decomposition processes involve mould fungi, yeasts and many other microorganisms; include several biological processes which are absolutely vital to maintaining a state of equilibrium in nature. Mould fungi very quickly bind any ammonia which is present in the first stage of the decomposition process to form ammonium nitrogen, which is subsequently available to plants as a slow release source of nitrogen. The harmful and unpleasant biogases are also largely eliminated, providing for a noticeable difference in the pit/lagoon and during application. Healthy, decomposed (rotted) slurry thus constitutes an important element of a closed substance cycle management system which benefits the soil, plants, animals and humans alike.

Activating sludge

The best solution is a simple method which activates the aerobic bacteria while avoiding the use of external energy and other factors detrimental to the environment. Penergetic g possesses the specific active properties to reactivates the life processes in slurry. The putrefactive bacteria die and the oxygen which is present in the slurry is aerobically activated. An oxygen-producing and breathing biomass quickly arises. The micro algae which develop change the colour of the slurry to dark green and the work performed by the bacteria renders the slurry homogeneous. In the course of time, existing floating layers and sedimentation layers dissolve. As a natural side-effect of these processes, the smell is diminished. Using the decomposed slurry produced with penergetic g enables the quantity of commercial fertilizer used to be reduced.

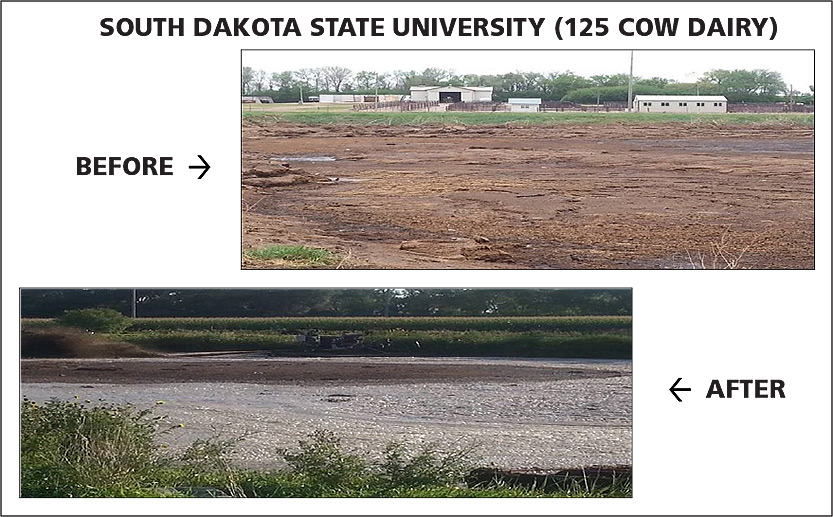

FIELD RESULTS

VIDEO (August 2017):

Details: The video shows the current condition of an eight foot (8’) deep manure pit (at a 48 cow tie stall dairy farm in Central Minnesota) that previously had a long history of heavy crusting and bottom sludge/residue and was always very hard to agitate and pump out. After five months of using Penergetic g/k, the manure loosed up so much that it became possible to extend a metal rod down into the pit and bounce it off the bottom (something that was never possible before).

Although the chronic manure problem rectified itself after five months, this video was shot 27 months after initiating Penergetic g/k treatment. Despite the heavy use of sawdust bedding, the manure in the pit (under a slatted floor) now consistently remains very liquid and dark in color without any added air, rainwater or agitation. The pit opening shown is part of three (3) conjoined pits. Now, twice yearly (mid-May and October) without any agitation these pits are pumped out completely – “right to the bottom”. The results have made a believer of the dairyman: “It is so easy to use and I can’t imagine ever not using it going forward.”

To review other examples of results with Penergetic g go to Trials and Testimonials

COST-BENEFIT ANALYSIS

INFORMATION DOWNLOADS

For more information on penergetic g the following downloads are available:

Also refer to Penergetic g results under Trails / Results

Penergetic g brochure (for dairy operations)

Penergetic g brochure (for swine operations)

Penergetic g for dairy slurry Pictograph

Penergetic g for pig slurry Pictograph

Manure Management Made Easy (for dairy operations)

Optimal Liquid Swine Manure Treatment

Penergetic g/k molasses flyer

Not All Manure is Created Equal

A Proven Approach to Treatment of Liquid Manure

Implications for Hog Farming

Measuring Ammonia Transformation

Application Report – Ramseyer Dairy Farm, Switzerland

(Sample) Penergetic Swine Manure Treatment Protocol

OMRI Product Registration (penergetic g)

OMRI Product Registration (penergetic g pig)

Farm Manure Management Calculator (FMMC)*

* (Optional) Complete the FMMC and submit by email or fax and receive a proposal (and cost) of using penergetic g at your operation.